Makers, you can develop an embedded system like an engineer.

Semiconductor manufacturers will often showcase their microcontrollers in an engineering evaluation board. These boards are loaded with features and peripherals that are useful in various ways, and because of this they are often relatively expensive. They are usually out of the reach of the Maker community, and even some of the smaller design houses may avoid them due to cost.

But the Maker Community has become home to several low cost microcontroller boards that could be used in an engineering development environment. At the very least, it will allow hardware engineers, or even hardware technicians, to set up a low cost minimum platform that can be turned over to microchip firmware programmers for initial development and testing.

But the Maker Community has become home to several low cost microcontroller boards that could be used in an engineering development environment. At the very least, it will allow hardware engineers, or even hardware technicians, to set up a low cost minimum platform that can be turned over to microchip firmware programmers for initial development and testing.

Even better, these boards can be coupled with low cost engineering-level hardware and software to provide a learning platform for those Makers who are interested in breaking into embedded systems programming.

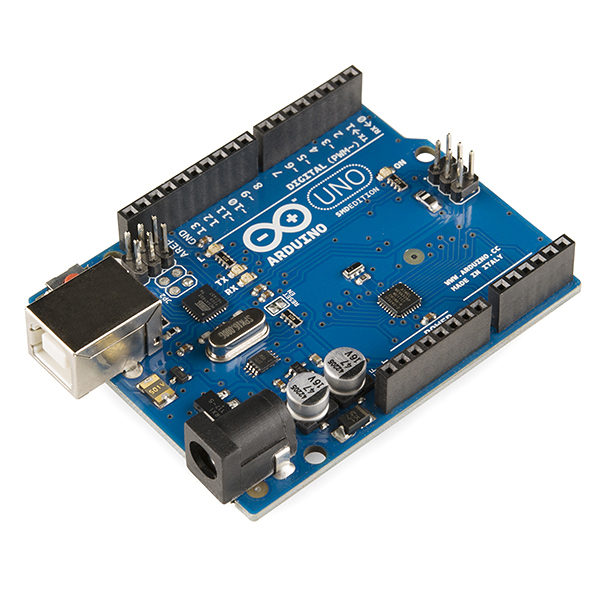

The main two boards used by the Maker community are the Arduino and the Arduino-compatible Microchip / Digilent chipKIT. These two boards are designed to be easy to program using the standard Arduino Integrated Development Environment (IDE). But there is nothing that requires the Arduino IDE. Instead, relatively inexpensive engineering-level microcontroller design tools can be applied to these Maker boards.

Almost 15 years ago I designed a product around the Hitachi SuperH SH-2 microcontroller. It was a wonderful device and very powerful for its time. It was the engine that drove the Sega Saturn game console. These microcontrollers required the use of an In-Circuit Emulator (ICE) and a bond-out processor that cost tens of thousands of dollars. The ICE emulated every part of the microcontroller, and was popped into the prototype PCB for the software developer. The ICE allowed the programmer to see quite a lot of what was happening inside the SuperH microcontroller – including individual registers in near real-time. Once the firmware was developed and troubleshot, it was packaged and sent to a parts distributor, who programmed the SH-2s for us before our production line added them to the circuit board. Firmware changes were made with the ICE, and added to our Production pipeline through change orders.

Today, in-circuit emulation has been mostly replaced by on-chip debugging hardware. The Joint Test Action Group industry association implemented standards for on-chip testing using a dedicated debug port on microcontrollers. These debug test access ports are used with a protocol that gives the engineer access to the device logic levels and registers.

Different manufacturers implement JTAG somewhat differently, and many manufacturers (Microchip, for example) have their own device serial debugging ports. This has led to the use of JTAG programmers for programming the printed circuit board in an Automated Test Equipment environment, and to manufacturer specific In-Circuit Debuggers (ICD) used for developing an embedded system.

ICE is expensive, and with newer microcontrollers it is unnecessary. JTAG programmers are useful, but not as useful as an ICD. And In-Circuit Debuggers have become cheap enough for the Maker Community to purchase.

ATMEL makes the AVR microcontroller that is used on the Arduino. And while a Maker could use the Arduino IDE to create something new, there is really nothing stopping anyone from using the ATMEL engineering design system. The ATMEL IDE, Atmel Studio 7, can be downloaded for free. ATMEL recommends several different ICDs, from low-cost to professional level. The mid-range and low cost ICDs are under $60. The professional level ATMEL development ICD is about $660. All are useful for product development. The difference between the debuggers is mostly in the speed at which the ICD can communicate with the PC, which affects programming speed and the number and speed at which registers are displayed in the IDE.

Microchip (who recently purchased ATMEL) also has an IDE that you can download, called MPLAB. The most current version as of this writing is MPLAB X, and there is a version of MPLAB that can be used on the Cloud. Microchip has a lot of 3rd party ICDs and even more simple serial device programmers. It is quite possible to purchase an ICD for under $40 for the Microchip PIC microcontrollers. The Microchip “official” ICD is the ICD 3, a USB-connected ICD that is widely used for developing embedded systems. You can purchase the ICD 3 for about $280, including shipping, from Microchip Direct.

Microchip (who recently purchased ATMEL) also has an IDE that you can download, called MPLAB. The most current version as of this writing is MPLAB X, and there is a version of MPLAB that can be used on the Cloud. Microchip has a lot of 3rd party ICDs and even more simple serial device programmers. It is quite possible to purchase an ICD for under $40 for the Microchip PIC microcontrollers. The Microchip “official” ICD is the ICD 3, a USB-connected ICD that is widely used for developing embedded systems. You can purchase the ICD 3 for about $280, including shipping, from Microchip Direct.

So a member of the Maker community could purchase an Arduino Uno, download the Arduino Software IDE, and start programming almost immediately.

OR, a Maker could get an Arduino Uno, download Atmel Studio 7, check out the ATMEGA 328P datasheet (PDF), purchase one of the recommended ICDs, and then learn how to interface it with the Arduino’s microcontroller. A Maker could do the same thing with Microchip’s chipKIT using MPLAB and a PIC compatible ICD – or the Microchip ICD-3.

No, this won’t be as simple as the Arduino environment normally used by Makers, but this is a good start for learning how to really design an embedded system. This is an excellent opportunity for anyone interested in learning the basics of embedded systems design and programming.

And finally, Arduino and chipKIT are not the only players on the market. There are others that are compatible, or not compatible with the Arduino IDE. And each manufacturer has either its own IDE, or is compatible with an open source IDE.